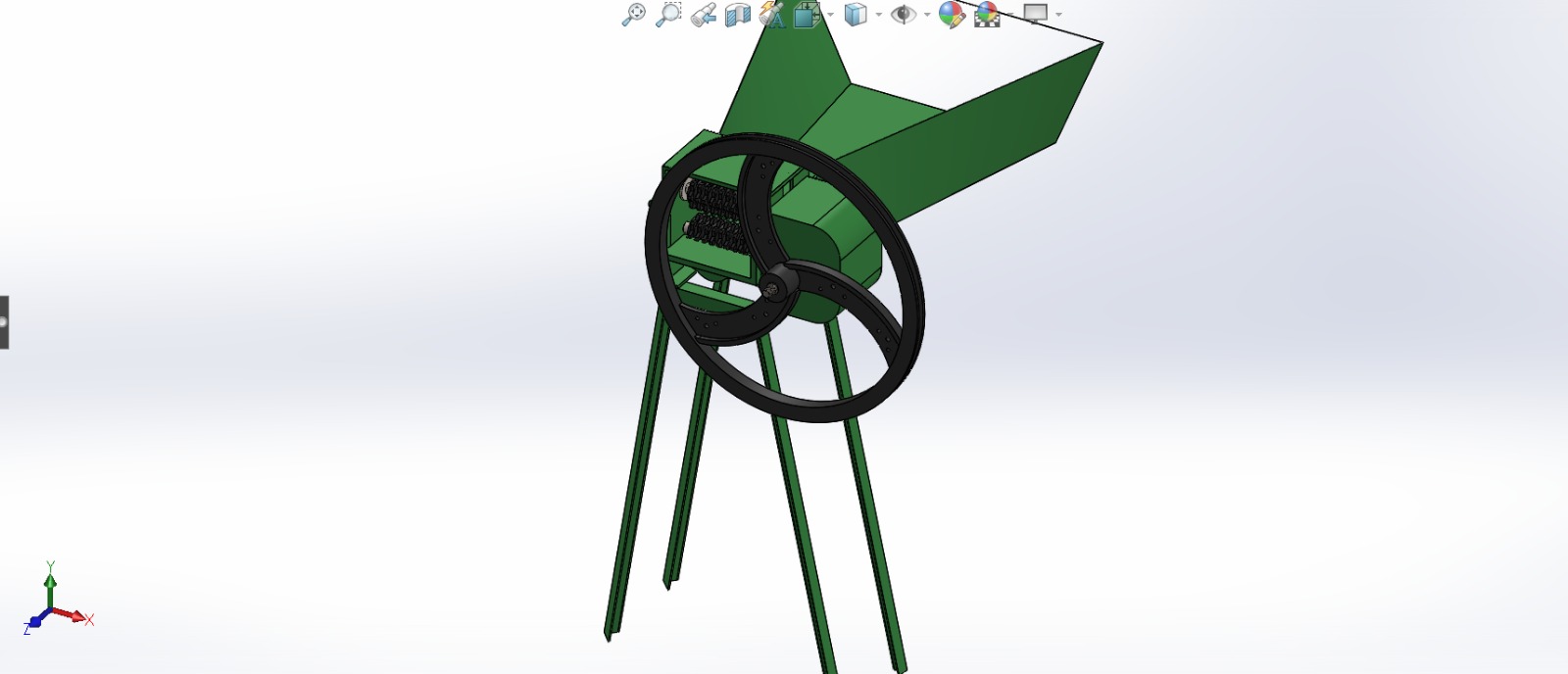

Hammer Crusher

Challenge

Rwanda Mines & Petroleum Board needed a heavy-duty aggregate processing solution capable of consistent throughput in demanding field conditions. The equipment had to handle hard stone and mineral materials while maintaining reliability over extended operational periods.

Solution

We engineered a robust hammer-crush mechanism with:

- Welded-steel frame optimized for impact loads and vibration absorption

- Replaceable hammer modules for minimal downtime and maintenance

- Precision bearing assemblies for smooth, consistent rotation

- Field-serviceable design with standard fasteners and accessible components

CAD modeling and tolerances ensured tight, reliable assemblies. All welded joints were structurally validated for durability under continuous operation.

Outcome

The Hammer Crusher was successfully delivered, installed on-site, and has delivered consistent aggregate processing performance. The replaceable-hammer design reduces maintenance intervals and operational downtime. Client reported reliable, predictable throughput meeting production targets.

Technical Specifications

- Frame material

- Welded structural steel, reinforced

- Primary mechanism

- Rotating hammer assembly with replaceable modules

- Bearing system

- Precision tapered roller bearings, sealed

- Design approach

- CAD modeling (SolidWorks), field-serviceable architecture

- Fabrication

- Complete in-house welding, assembly, and quality control