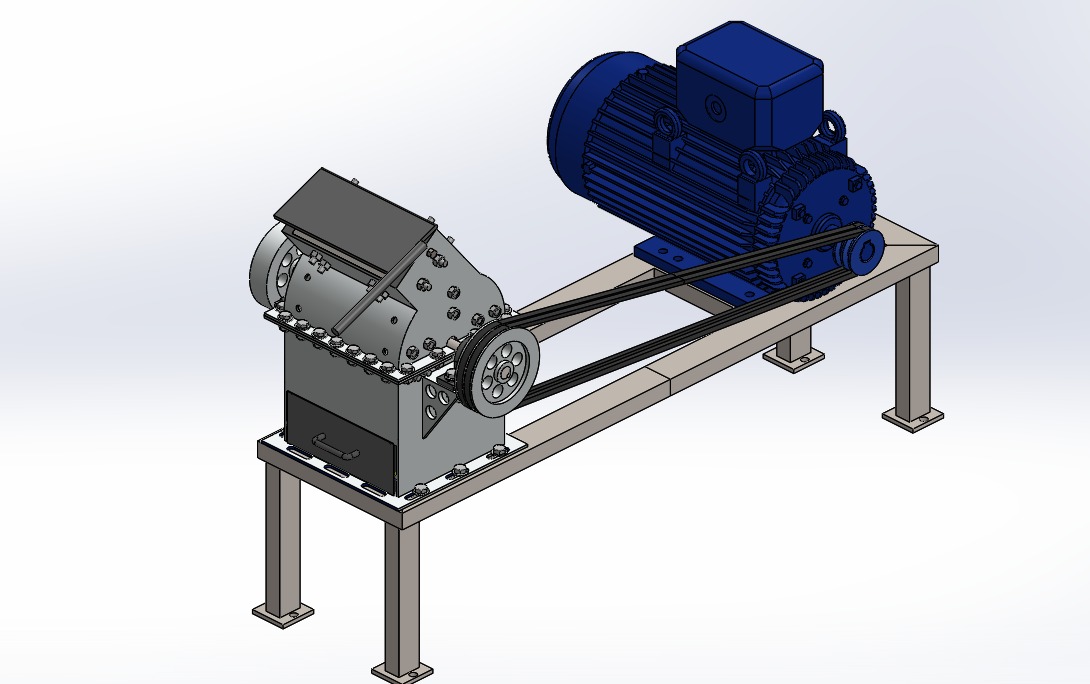

Pellets Extruder Machine

Challenge

Huye Prison required an in-house feed-pellet production capability for livestock management. The equipment needed to be robust, secure, and simple enough for institutional staff to operate and maintain without specialized expertise.

Solution

We designed and engineered a complete pellet-production system with:

- Motorized feed-roller assembly for consistent material compression

- Temperature and pressure controls for pellet quality

- Stainless-steel contact surfaces for sanitation and durability

- Emergency stop and safety interlocks for secure operation

- Comprehensive operator documentation and on-site training

The entire system was modeled and optimized for reliability under continuous institutional use. All components were selected for long service life and local replaceability.

Outcome

The Pellets Extruder was successfully commissioned at Huye Prison. Staff rapidly mastered operation and maintenance. The system delivers reliable feed production, reducing external procurement and enabling the institution to produce customized feed blends for their livestock operations.

Technical Specifications

- Primary mechanism

- Motorized roller-compression assembly

- Contact materials

- Stainless steel and hardened steel rollers

- Control system

- Mechanical and electrical safety interlocks, emergency stop

- Production capacity

- Designed for institutional batch operation

- Documentation

- Complete assembly drawings, operator manual, maintenance guide

- Commissioning

- On-site installation and operator training included